Five Advantages Of Products

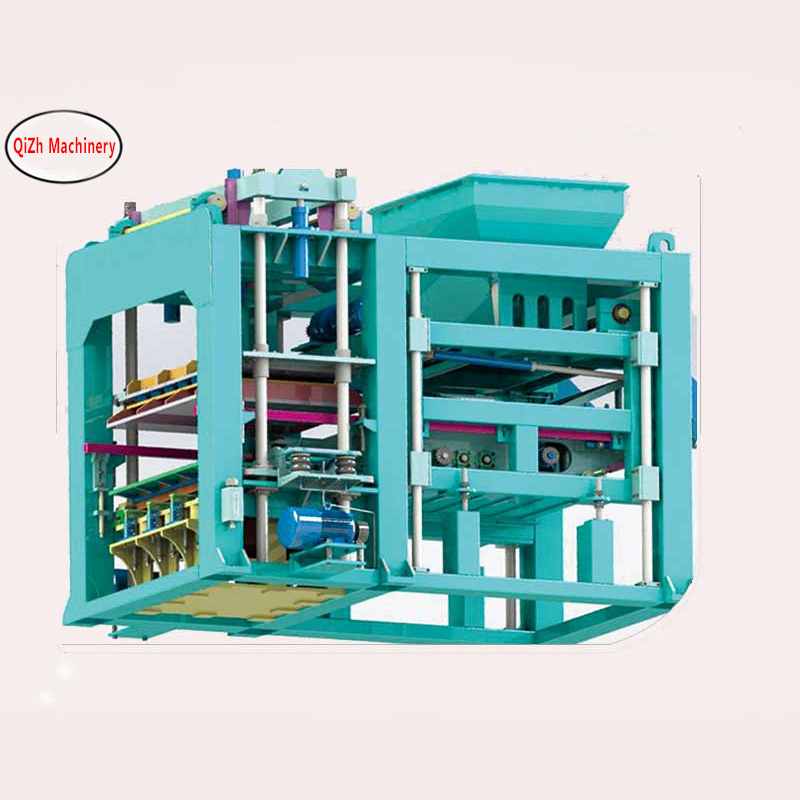

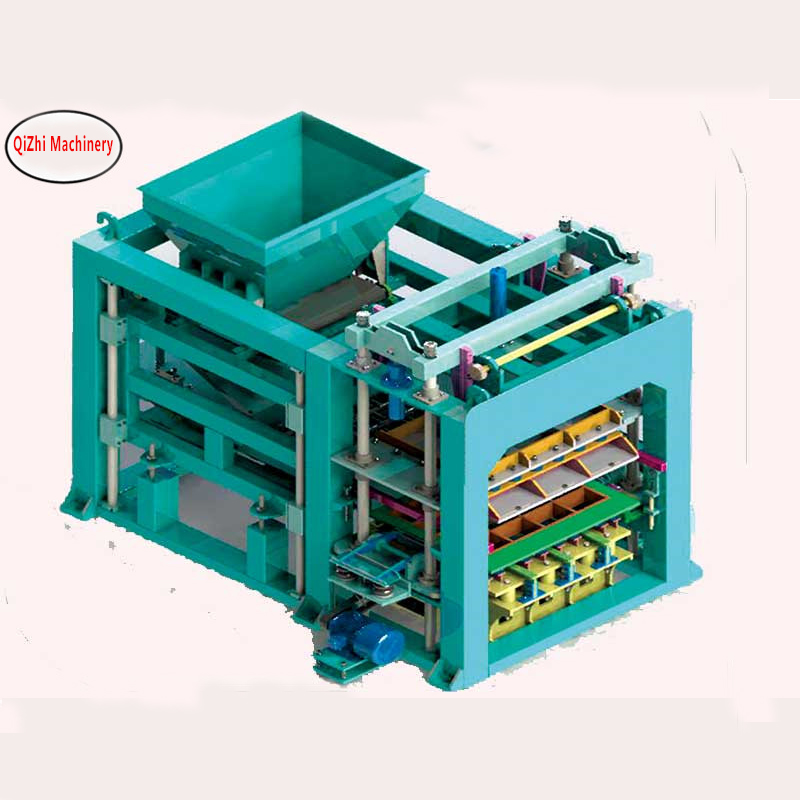

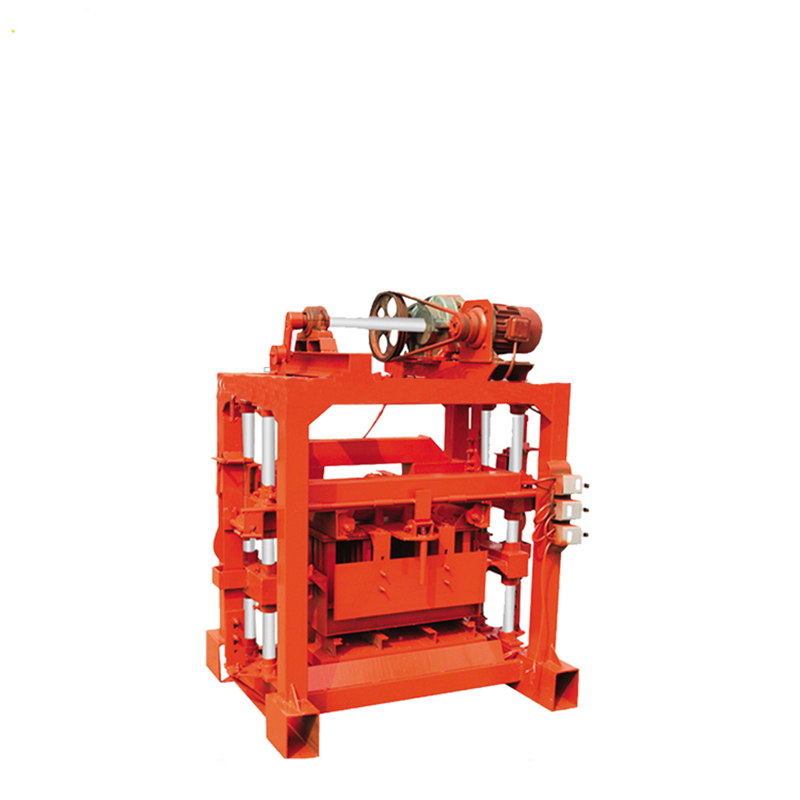

- forming machine frame: made of high strength pot and special welding technology, and its firmness.

- guide column: made of super strong special steel, chrome plated with good twist resistance and wear resistance.

- die cavity head: electro-hydraulic synchronous drive, the same pallet product height error is very small, product consistency is good.

- Cloth feeder: using the sensing and hydraulic proportional drive technology, under the action of wobble technology arch breaking mechanism, it produces forced leaxin discharge, the cloth is fast and uniform, and it is beneficial to the thin-walled and multi row of holes.

- Vibrator: electro-hydraulic technology driven, multi source vibration system, under the control of the computer controlled by the hydraulic driven vertical synchronous vibration, frequency can be investigated, low frequency charging, high frequency molding working principle, the different raw materials can get good vibration effect, vibration acceleration can be 17.5 stages.

Product Details

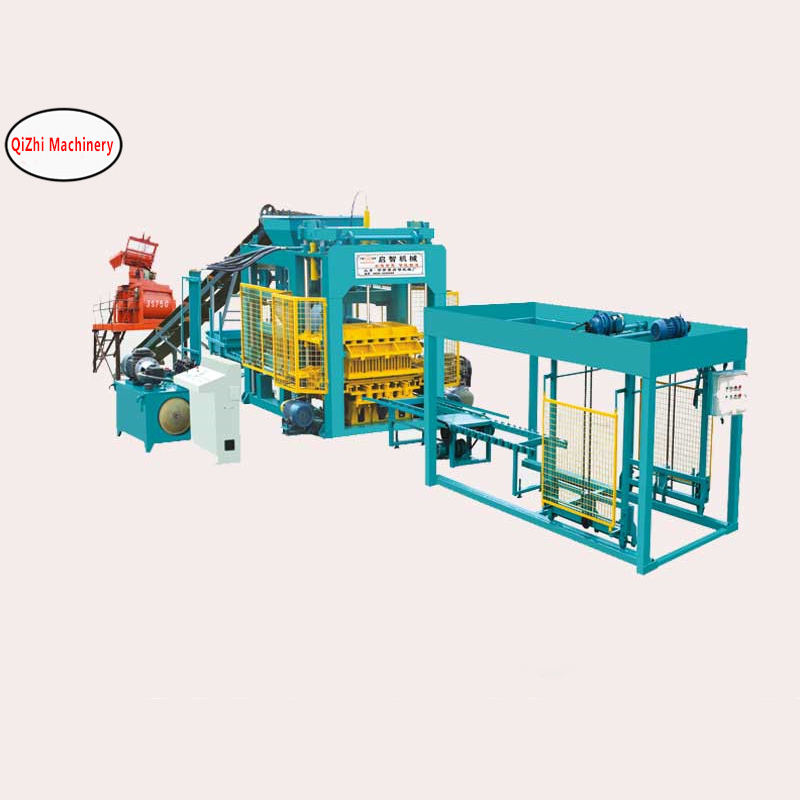

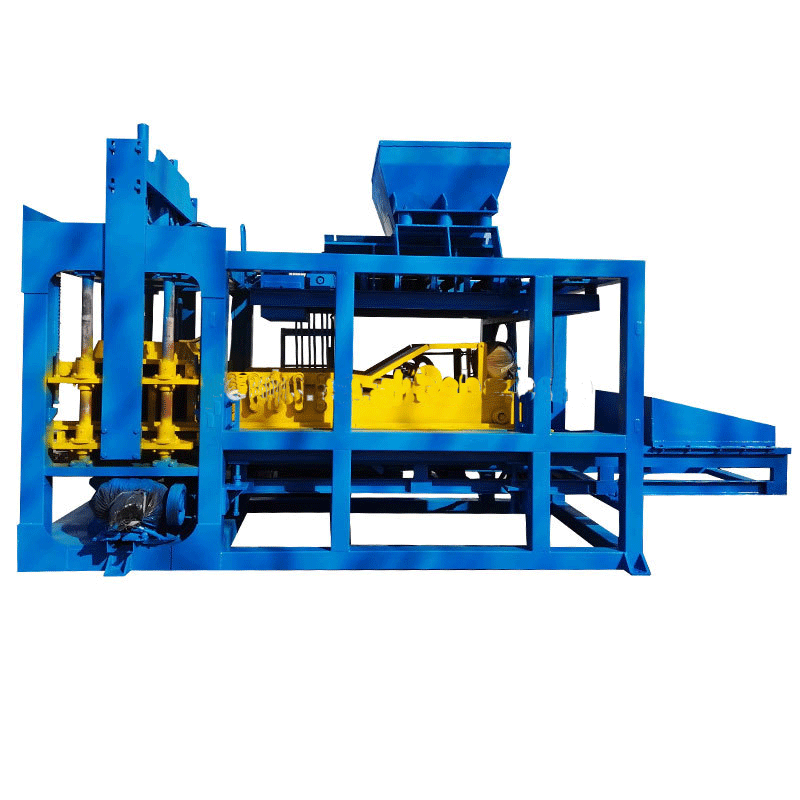

QT8-15A type full automatic block forming machine

forming machine frame: made of high strength pot and special welding technology, and its firmness.

2. guide column: made of super strong special steel, chrome plated with good twist resistance and wear resistance.

3. die cavity head: electro-hydraulic synchronous drive, the same pallet product height error is very small, product consistency is good.

4. cloth feeder: using the sensing and hydraulic proportional drive technology, under the action of wobble technology arch breaking mechanism, it produces forced leaxin discharge, the cloth is fast and uniform, and it is beneficial to the thin-walled and multi row of holes. 5. vibrators: electro-hydraulic technology driven, multi source vibration system, under the control of the computer controlled by the hydraulic driven vertical synchronous vibration, frequency can be investigated, low frequency charging, high frequency molding working principle, the different raw materials can get good vibration effect, vibration and speed can be 17.5.

6. control system: computer control, man-machine interface, electric appliance with Japanese Fuji and other brands, control program integrated 15 years of practical production experience, integrated international development trend and research and development to meet the national conditions design, without professional people, only simple training can be done, the need for powerful memory to upgrade.

7. material feeding device: the supply of materials is controlled by the computer to avoid the internal pressure caused by the influence of the material first, to ensure the uniform supply of the material, so that the error of the strength of the products is very small.